What is KAIZEN™

Dive into the KAIZEN™ methodology

Improving the World with

Everyone, Everywhere, Every Day

– The KAIZEN™ way

Definition of KAIZEN™

Over 30 years ago, Masaaki Imai sat down to pen the groundbreaking book ‘Kaizen: The Key to Japan’s Competitive Success’ (McGraw Hill). Through this book, the term KAIZEN™ was introduced in the western world. Today KAIZEN™ is recognized worldwide as an essential pillar of an organization’s long-term competitive strategy. Since introducing this term as a systematic approach to business improvement, companies that implement KAIZEN™ have continually yielded superior results.

“KAIZEN™ means improvement. Moreover, it means continuing improvement in personal life, home life, social life, and working life. When applied to the workplace KAIZEN™ means continuing improvement involving everyone – managers and workers alike.”

Masaaki Imai, Founder of Kaizen Institute

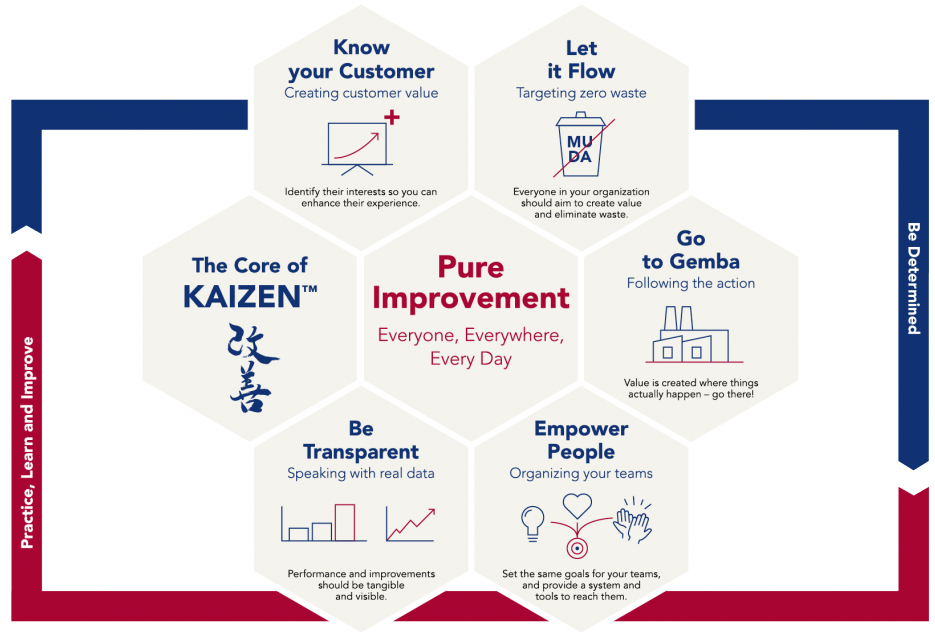

The Core of KAIZEN™

Level up you KAIZEN™ Skills

Discover our training offers and how we can support your organization implement Continuous Improvement

Want to know more?

Go back to basics and learn more about the KAIZEN™ terminology that reinforces the KAIZEN™ culture

KAIZEN™ Methodology Development History

The KAIZEN™ methodology has gradually developed over many decades. It was publicly and officially introduced to the world in the 1980s as a systematic methodology through the best-selling book “KAIZEN™” by Masaaki Imai, the founder of Kaizen Institute.

1930

Masaaki Imai is born in Tokyo, Japan. The first domestic automotive production is planned in Japan, and the Just-In-Time concept is observed.

1940

World War II to post-war economic reform period commences in Japan.

1950

Imai works at the Japan Productivity Center in the USA and accompanies Japanese executives to visit and learn from US manufacturers. Japanese companies gain strength in their quality and worldwide competitiveness.

1960

Imai works with Shoichiro Toyoda to observe the American way of business.

1980

Imai works internationally with Taiichi Ohno to spread the message of the Toyota Production System (TPS).

1986

KAIZEN™ is introduced to the world for the first time, as a systematic management methodology.

1990’s

KAIZEN™ appears for the first time as a word in the Oxford dictionary.

The term Lean was coined.

Lean concepts are promoted through various publications, to include Imai’s GEMBAKAIZEN™ book.

Tools, such as Six Sigma, gain popularity though clouding the importance of a systematic approach.

Kaizen Institute continues to offer practical, hands-on methods that fit the local culture and business practice, when implementing KAIZEN™ within organizations.

2000’s

KAIZEN™ Management System (KMS) is developed, to help companies to improve based on a systematic QCD Model.

KAIZEN™ Change Model (KCM) is added to enhance a KAIZEN™ culture, mindset and behaviors of the organization.

Many corporations start developing their own improvement strategies based on KAIZEN™, seeking to gain sustainable improvements and a competitive advantage within their markets.

Today

KAIZEN™ Business System (KBS) supports organizations to achieve Continuous Improvement and sustainable growth.

Kaizen Institute continues to spearhead global development for the KAIZEN™ methodology, bringing awareness to Everyone, Everywhere, Everyday.